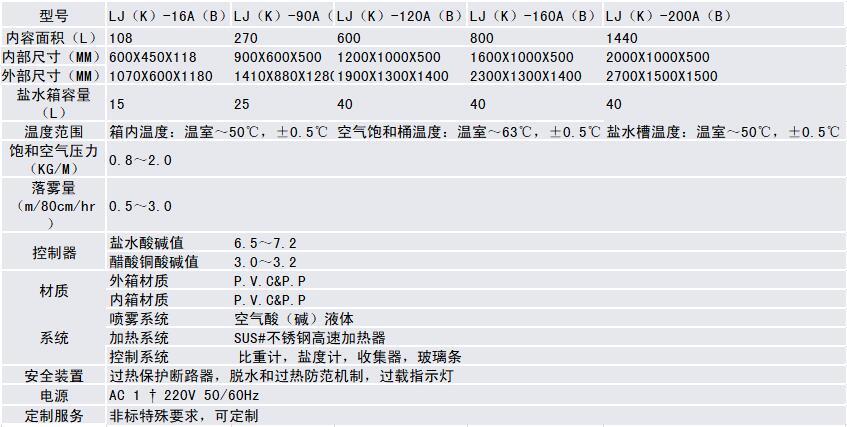

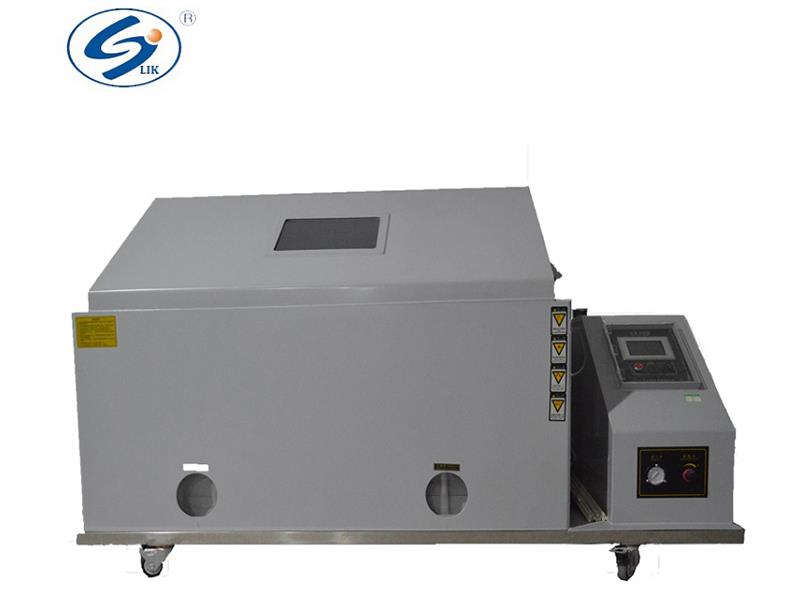

Compound salt spray test chamber

The compound salt spray test chamber is capable of checking the salt spray corrosion of the data and its protective layer, as well as the process quality comparison of similar protective layers, and at the same time checking the ability of some products to resist salt spray corrosion; applicable to parts and electronics Salt spray corrosion test of components, metal materials and industrial products.

It is used to accelerate corrosion experiments on protective layers, parts, electronic devices and industrial products of metal materials, and to reproduce the corrosion process of sprayed and untreated metal surfaces quickly and easily. It checks the ability to corrode the data and its protective layer, as well as the process quality of similar protective layers, and also checks the ability of certain products to resist corrosion.

1. The composite salt spray experiment box uses automatic or manual watering system. When the water level is lacking, it can automatically compensate the water level function, and the experiment is not stopped.

2. Fine glass nozzle, the mist is evenly dispersed, and naturally falls on the test piece, and no crystal and blockage are guaranteed.

3. With two layers of over-temperature protection, the water level lacks warning to ensure safe use.

4. The temperature controller uses a digital display, PID control, and an error of ±0.1 °C. The laboratory uses a direct steam heating method to increase the temperature and speed evenly and reduce the standby time.

5. The spray tower is equipped with a cone disperser, which guides the mist, adjusts the amount of fog and uniform fog.

6. The saturated air tank is heated and humidified and provides the humidity required by the laboratory.

1. Use the LCD digital display color touch screen temperature and humidity controller (LK8600) to record the temperature and humidity test curve thoroughly.

2. Control method: temperature, humidity, temperature and humidity can be used to control the program.

3. Program group capacity: 140Pattern (group) 1400Step (segment) Each group of programs *** can be set to Repest99 segment.

4. The time for each performance form can be arbitrarily set to 0-999 hours and 59 minutes.

5. Each group can arbitrarily set part of the cycle 1-999 times or all cycles 1-999 times.

6. With power-off memory function, after the re-powering, the end-of-end experiment can be carried out.

7. It can be connected to the computer with RS232 interface.