Rapid temperature change test chamber

1. The rapid temperature change test box is suitable for the defense industry, aviation industry, automation components, automotive parts, electronic and electrical exterior components, electrical products, plastics, chemical industry, food industry, pharmaceutical industry and related products in the surrounding atmospheric temperature. Adaptation experiments (shocks) under drastic changes in conditions.

2. The rapid temperature change test chamber is suitable for adaptability experiments and stress selection experiments under the conditions of rapid temperature change or gradual change of instruments, appearances, electricians, electronic products and parts, so as to test the function of the sample under the prescribed conditions. Behavior analysis and evaluation.

1. Arc shape and matte line treatment, high-quality appearance, and the use of flat no reaction handle, easy to operate, safe and reliable;

2. The rapid temperature change experiment box uses Philips lighting window light and built-in high temperature demisting equipment to facilitate observation of the product experiment in the box;

3. It is equipped with anti-vibration table mats, which makes the machine stand quiet and stable during operation. 6. It has various protection equipments, and its function is safe and reliable.

4, the rapid temperature change experiment box selects the liquid crystal display touch screen controller, the screen operation is simple, the program is simple to modify, and has an RS-232 computer interface;

5, the manipulator operation interface set Chinese and English characters to be selected, can be connected to computer operation, control;

6. The rapid high and low temperature change experiment box uses French imported compressors and uses all environmentally friendly refrigerants R23 and R404.

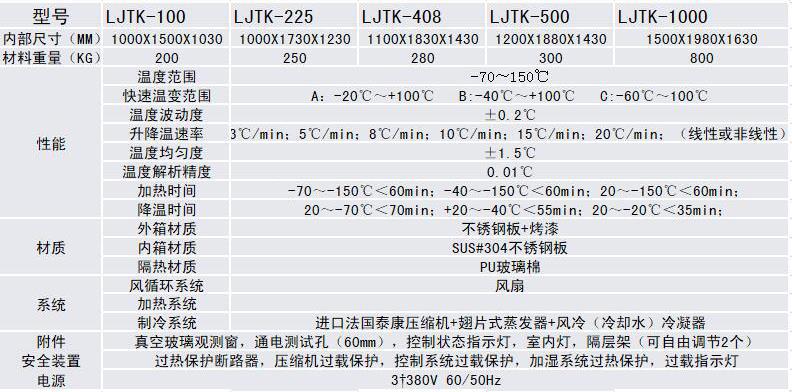

1. Inner box material: SUS304 stainless steel plate. Outer box materials: SEEC steel plate plus powder paint to increase the appearance and cleanliness.

2, insulation layer: the use of high-strength PU foam and high-density fiberglass cotton to avoid unnecessary energy loss.

3. The test door and the body are made of high-low temperature and high-tension sealing strips to ensure the sealing of the test area.

4. Temperature measuring body: PT100.

5. The box body is formed by CNC digital working machine, the arc shape is beautiful and generous, and the plane has no reaction handle, which is easy to operate.

6, large large observation window with lighting, using the built-in glass in the heat body, always adhere to the situation in the clear observation window.

7. The test hole with a diameter of 50mm prefabricated on the left side of the box body can be used for external test power line or signal line.

8. The bottom of the machine is made of high quality fixed movable wheel for fixing and moving.

9. The drainage system uses the vortex type and U-shaped accumulation equipment to drain.

10. The anti-sweat machine is treated with the heat of the system K-tube for anti-sweat treatment.

11, acrylic control panel.

1. GB10589-89 low temperature test box skill conditions;

2. GB11158-89 high temperature experiment box skill conditions;

3. GB10592-89 high and low temperature experimental box skill conditions;

4. GB2423.1 low temperature experiment, experiment A;

5. GB2423.2 high temperature experiment, experiment B;

6. GB2423.22 temperature change experiment, experiment N;

7. IEC68-2-1 Experiment A;

8. IEC68-2-2 Experiment B;

9. IEC68-2-14 Experiment N.