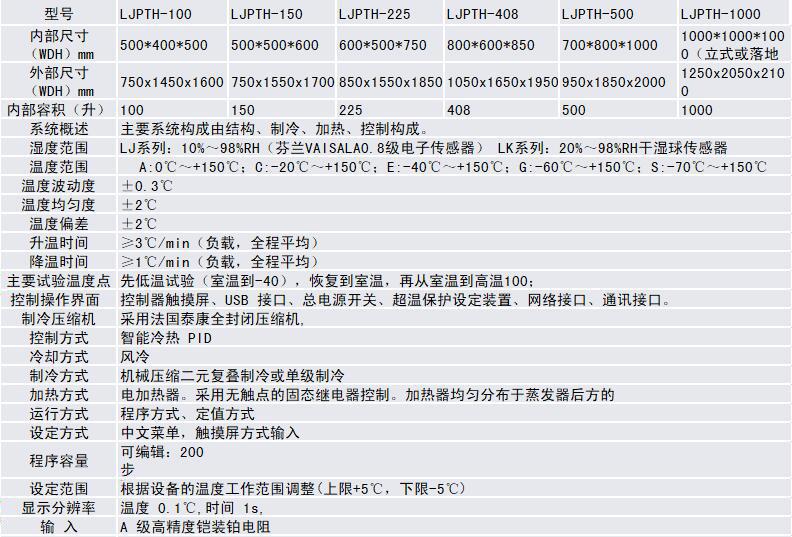

Programmable constant temperature and humidity test chamber

It is suitable for determining the suitability of components, equipment or other products for use, transport and storage under combination of high and low temperature and temperature cycling. And equipment for evaluating use in high temperature or low temperature environments. Widely used in military, aerospace, electronics, automotive, new energy, testing and other industries.

First, the precise control of the refrigeration system

The main configuration adopts imported brand parts, which can ensure the optimized compressor ratio and the ratio of the whole refrigeration system. When the compressor needs to be opened, the central controller controls the refrigerant flow rate according to different temperature points to control the cooling capacity. To keep the device running in a relatively low power state. In the design of the refrigeration system, the protection measures for the compressor are fully considered, such as the automatic adjustment and protection function of the compressor return air temperature. This function keeps the operating temperature of the compressor within the normal temperature range, and prevents the compressor from being too cold or overheated. Extend the life of the compressor. The high-quality oxygen-free copper tube gas protection welding method is adopted in the pipeline welding of the refrigeration system, which avoids the damage caused by the oxide generated on the inner wall of the copper tube to the refrigeration system and the compressor by the conventional welding method. In the design of the refrigeration system, the vibration reduction measures during the operation of the unit are fully considered. For example, the compressor is equipped with a spring damper, and the arc-bending method is adopted on the refrigeration pipe to avoid the deformation of the pipe caused by the vibration and temperature changes. Leakage, thereby improving the reliability of the entire refrigeration system;

Second, reasonable air duct design

Improve the mature simulation air volume simulation system, through the advanced air duct design, according to the requirements of whether to do the upper and lower transport or horizontal transport wind, to ensure the temperature uniformity and fluctuation of the environmental test chamber, and effectively control the frosting phenomenon of the evaporator, Since its establishment, Lijia has continuously broken through the technical indicators of uniformity ±2, ±1, ±0.5, ±0.3, ±0.2.

Third, the excellent adjustment method

high-precision computer linear refrigerant flow servo control temperature regulation and humidity control system, PID+FUZZY way to control the refrigerant flow, to achieve low energy consumption, low noise. Due to the advanced linear refrigerant control technology, its reliability and control accuracy are greatly improved.

Fourth, efficient condensing evaporator (water cooling)

Advantages of the plate heat exchanger: 25% of the shell-and-tube heat exchanger with compact structure, small volume and weight of only the same heat transfer area, the equivalent diameter of the plate heat exchanger is small, the flow disturbance is large, and the Reynolds number is small. The turbulent flow can be formed underneath, so the heat transfer coefficient is high, generally 1.5 times that of the shell-and-tube heat exchanger. The refrigerant charge small-temperature tank adopts a plate type double-stage brazed heat exchanger in the refrigeration system. It overcomes the shortcomings of large size, poor heat transfer and low efficiency of the domestic cryogenic equipment.

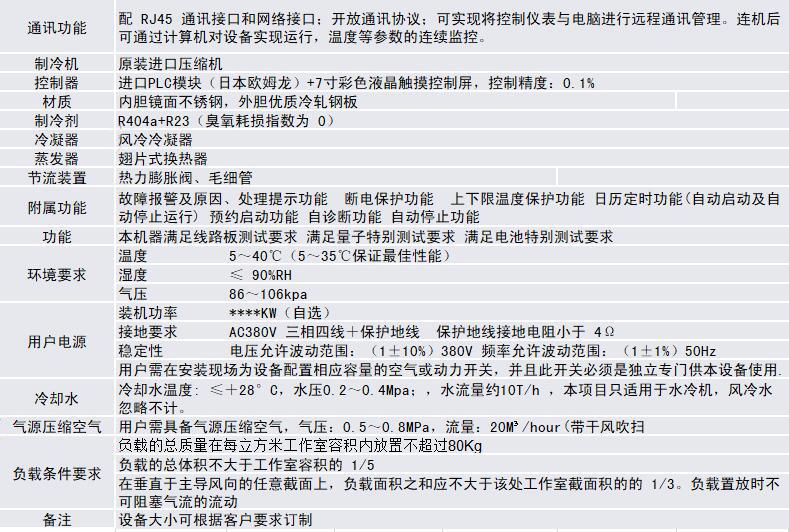

Five, intelligent master controller

Through the internet network, you can simultaneously view and operate the controller through the iPad and mobile phone in any place with a network, and develop independently. Based on the main interface of WIN10 operation, the compressor can be expanded: current, pressure and flow. Multi-channel temperature and humidity collection of the box.

The software runs directly on the computer and can be used directly on any computer, making it as convenient as operating a computer.

1. It can be integrated with the system of any open source equipment in the world, such as gantry, charging and discharging machine, rotating hub and so on.

2, the amount of data storage depends on the computer hard disk, there is no problem of insufficient memory space.

3, the operation is very smooth, even in the remote large amount of data exchange there is no carton problem.

4, the number of program groups: 200, the number of steps: 200 steps, can be upgraded more.

5, control input endpoints: 16, control output endpoints 16, temperature control channels: 1, humidity control channels: 1. Can be upgraded more.

6, upgradeable features:

WiFi remote monitoring for remote control of mobile apps. And Ethernet network monitoring. It can serve as a server to serve multiple clients at the same time, such as real-time monitoring of transmission files.

1. Studio: Independent studio over-temperature protector Fan overheat protection;

2, refrigeration system: compressor overpressure protection compressor overcurrent protection compressor overheat protection;

3, the power system: power supply short circuit protection heater short circuit and other overcurrent protection;

4. Others: Grounding protection of the test box casing.

1. GB/T2423.1-2008 Test A: Low temperature test method

2. GB/T2423.2-2008 Test A: High temperature test method

3, GB/T11158-2008 high temperature test box technical conditions

4, GB/T11158-2008 low temperature test box technical conditions

5, GB/T2423.2-2008 Test B: High temperature test method

6, GJB150.4-2009 low temperature test

7. GB/T2423.3-2008 constant damp heat test

8, GJB150.3-2009 high temperature test

9. GJB150.9-2009 Test Standard Requirements for Damp Heat Test

10, GB/T5170.2-2008 temperature test equipment

11. GB/T GB/T 2423.22-2008 Test Nb: Temperature change test

12. GB/T GB/T 2423.22-2008 Test Nb: alternating heat and humidity test

1. Installation and commissioning: After the buyer prepares the external conditions (such as electricity) required by the equipment, the seller is responsible for the installation, commissioning and start-up of the equipment, and provides good technical support and after-sales service.

2. Final acceptance and training: The final acceptance of the purchased equipment is carried out at the buyer's site, and the seller's technical engineer participates. At the same time, the on-site training of the equipment at the domestic buyer's location is provided, so that the trainees can independently and skillfully operate the equipment and complete simple maintenance work and routine maintenance of the equipment. Waiting for work.

3. Warranty: The warranty period of the equipment is 12 months, and the official effective date is the buyer's acceptance certificate for the equipment.

4. Maintenance reaction time: Within 1 hour, the seller will respond within 1 hour after receiving the buyer's fault notification, and rush to the user's site within 24 hours to eliminate the fault as soon as possible.

5. Lifelong service project: The seller promises to provide technical support for the equipment during the period of use of the equipment.