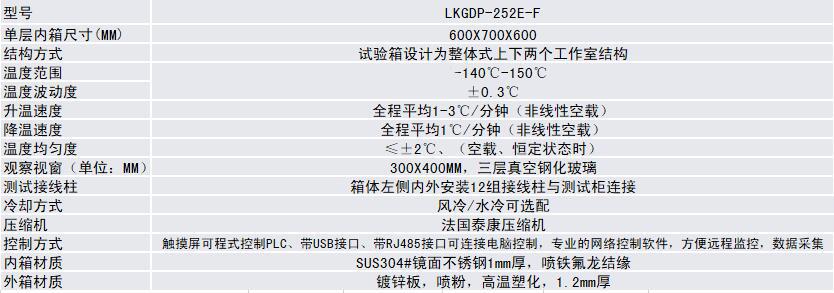

Double-layer explosion-proof high and low temperature test chamber

This equipment adopts single-machine double-box design, one test box on the top and bottom, and the control system and refrigeration system of the two cabinets are completely independent. The overall appearance is elegant, safe and reliable, and will not hurt the staff. If you have a need for a low pressure test chamber, please call us for detailed consultation.

The casters at the bottom of the test box are conveniently moved; 4 sets of universal wheels are installed at the bottom of the box, and the front two casters are provided with a self-locking function to facilitate the movement and fixation of the equipment;

The second explosion-proof design: the front and rear pressure relief doors of the cabinet are equipped with explosion-proof chains. When the battery explosion forms a great impact force to open the equipment door, the explosion-proof chain acts as a buffer to prevent the door from being completely opened or washed away. Fly out to avoid secondary damage;

Reinforced hinge and explosion-proof lock design: The hinged connection between the explosion-proof door and the box is made of reinforced 304# stainless steel. At the same time, the door lock uses strong flat lock to ensure the safety of the equipment.

High-quality insulation design: The insulation layer of the cabinet is designed to be 100mm thick, and the high-temperature resistant rock wool with extremely low thermal conductivity is selected as the thermal insulation material, the thermal insulation effect is good, and the heat loss is extremely small;

Side-side terminal design: 12 sets of copper terminals for testing are installed next to each box. There is an insulated Teflon sleeve between the terminal and the box. Sealing and energizing will not leak.

Explosion-proof pressure relief design on the side: The active explosion-proof pressure relief port is installed next to each box, and the pressure is automatically released once the induction pressure is applied.

GB/T2423.1-2008 (IEC60068-2-1:2007) low temperature experimental method.

GB/T2423.2-2008 (IEC60068-2-2:2007) high temperature experimental method.

GJB150.3-1986 high temperature experiment;

CJB150..4-1986 low temperature experiment;

GB/T 31485-2015 electric vehicle power battery safety requirements and experimental methods.

This product consists of a refrigeration system, heating system, control system, forced internal circulation system, smoke exhaust box, explosion-proof system and other parts.